Resources

Literature / Specifications

Battery Data Sheets

Safety Data Sheet

FAQs

‣ When should I replace a Hawker® battery?

A Hawker® battery is considered to be at the end of its expected operation life when one or more of the following applies:

- during an Open Circuit Voltage (OCV) test, a fully-charged battery measures less than 12.65 volts, then the battery should be replaced, and/or

- during a Capacity test, a fully-charged battery fails to provide at least 80% of the battery’s rated Capacity when discharged at a specified C-rate (e.g., for a Hawker® ARMASAFE™ Plus 6TAGM battery, when discharged at the C20 rate, if the battery measures less than 96 Ah, then the battery should be replaced.), and/or

- during a conductance analysis test, a fully-charged battery fails to provide at least 80% of the battery’s rated CCAs (e.g., if a Hawker® ARMASAFE™ Plus 6TAGM battery measures less than 980 CCAs, then battery should be replaced), and/or

- during a mechanic’s load test, a fully-charged battery fails to remain above 9.9 volts Closed Circuit Voltage (CCV; a.k.a., load voltage) during the load test. The specified load should be equal to 1/2 of the battery’s rated CCAs and be applied for 15 seconds (e.g., for a Hawker® ARMASAFE™ Plus 6TAGM battery, apply a 612.5 amp load for 15 seconds, during which the battery’s load voltage must remain at 10.0 volts CCV or higher, if not, then the battery should be replaced. Note: Per TB 9-6140-252-13, military personnel are only required to apply a 550-amp load on the Hawker® ARMASAFE™ Plus 6TAGM battery, since MIL-PRF-32143C only requires a new 6TAGM battery to be at least 1100 CCA).

However, though a battery passes the OCV test and one or more of the other three above tests, be careful not to mix identical batteries that have developed significantly different capabilities (usually, the result of plate sulfation as batteries age). For example, in a parallel, series, or series-parallel configuration:

- during an Open Circuit Voltage (OCV) test, ensure all fully-charged batteries are within a 0.15 volt OCV range of each other (e.g., if the highest battery measures 12.9 volts OCV, then the lowest battery should measure no less than 12.75 volts OCV.), and

- during a Capacity test, ensure all fully-charged batteries are within a 10% Ah range of each other when discharged at a specified C-rate (e.g., if the highest Capacity battery measures 120 Ah (C20), then all batteries should be within 12 Ah range of each other, so the lowest Capacity battery should measure no less than 108 Ah (C20)), or

- during a conductance analysis test, ensure all fully-charged batteries are within a 10% CCA range of each other (e.g., if the highest battery measures 1225 CCAs, then the lowest battery should measure no less than 1102.5 CCAs), or

- during a mechanic’s load test, ensure all fully-charged batteries are within a 0.4 volt CCV range of each other (e.g., if the highest battery measures 11.2 volts CCV, then the lowest battery should measure no less than 10.8 volts CCV).

‣ How to choose the correct battery?

The Hawker® ARMASAFE™ Plus 6TAGM battery (NSN: 6140-01-485-1472) is a direct drop-in replacement battery for any tactical/combat vehicle or equipment where the NATO 6T-size 12-volt flooded-cell battery was previously installed (e.g., 6TMF, 6TL, 6TN, etc.). If the vehicle or equipment requires a different size 12-volt battery, please see the Hawker® MIL PC battery page to find the appropriate battery based on either the BCI group size or your current battery’s dimensions and battery terminal type, or simply contact us on the web or call the Hawker® Hotline at 877.485.1472 so we may suggest a replacement battery.

View the comparison between the Hawker® ARMASAFE™ Plus 6TAGM battery vs. the 6TMF battery.

‣ Why do some Hawker® MILPC and Odyssey® batteries have an additional foam insert as part of the packaging?

In order to mitigate unintentional damage to boxed batteries that are shipped individually via parcel carrier, EnerSys® improved the packaging for all Hawker® MILPC & Odyssey® batteries within BCI Group 31. The new design provides increased protection with the placement of a high density foam sheet (1/2 inch) atop the current laminated cardboard protective insert that encases the top of the battery. The box is then sealed. Furthermore, we are developing similar improvements for all BCI group-sized batteries (e.g., G34, G78, G65, etc.). Note: This change does not affect non-boxed batteries that are bulk shipped on shrink-wrapped pallets.

‣ What does BCI mean?

BCI is an acronym for Battery Council International. BCI is a trade association that provides industry standards for the sizing, types, and testing of lead-acid batteries. For example, a BCI Group 34 battery’s dimensions should be approximately 10 1/4”L x 6 13/16” W x 7 7/8”H (260mm L x 173mm W x 200mm H), have standard SAE (Society of Automotive Engineers) battery terminal posts, with the positive (+) post on the top of the battery near the forward-left corner and the negative (-) post on the top of the battery near the forward-right corner. Often, the battery group size is indicated in the battery model (e.g., the Hawker® MIL PC G31 SAE is a BCI Group 31 battery). Typically, an “R” designation in the model number refers to a battery where the positive (+) and negative (-) battery terminals have been swapped from their normal BCI group size standard position (e.g., see ODYSSEY® battery model 34-PC1500 vs the 34R-PC1500T).

‣ What are battery terminals?

Battery terminals are the electrical contact points used to connect to a load (e.g., a vehicle, a generator, a winch, etc.) or a battery charger. One battery terminal is marked positive (+) and the other is marked negative (-). For standard vehicle batteries, the battery terminals are normally on the top of the battery, but may also be found on the side (e.g., see BCI Group 75 and Group 78 battery designs). In the United States, typically the terminals will be standard SAE battery terminal posts (most widely used), threaded studs, or threaded receptacles.

‣ Is it necessary to apply a treatment to Hawker® Battery terminals to prevent corrosion?

Under normal operating conditions, no. Normally, battery terminal corrosion occurs because electrolyte comes in contact with a battery’s lead terminals, thereby forming lead-sulfate. Initially, lead-sulfate corrosion typically appears as a white or grayish powdery substance, but over time will appear as a solid, crusty formation. This corrosion can occur if the battery is overfilled, there is electrolyte leakage, or the battery off-gasses. Since Hawker® AGM batteries are sealed and virtually don’t off-gas (very nominally), as well as the fact the Hawker® battery terminals are made from stainless-steel (coated with tin), the terminals should not exhibit lead-sulfate corrosion. That said, in certain extreme conditions, such as continuous exposure to air containing a salt mist, galvanic (not lead-sulfate) corrosion may occur. Galvanic corrosion on a lead-acid battery typically appears as a powdery greenish or bluish substance. If galvanic terminal corrosion is noted, clean the battery’s terminals and the equipment’s terminal connectors with a wire brush (removing all corrosion), then wipe away any remaining traces with a damp rag. After all components have dried, reconnect the terminal connectors to the battery. Then, apply the following approved coating to the battery’s terminals & connectors: NO-OX-ID A® (Product Code 5000-N), by Sanchem Inc. It’s recommended that the end-user do not use any other treatment, as they have not been tested by EnerSys®.

‣ What is lead-sulfate?

Lead-sulfate is a chemical (crystalline) compound that forms on lead-acid battery plates during the discharge process (and, as stated above, can occur on the terminals of flooded cell batteries). It’s a chemical byproduct produced by a natural chemical process that must occur on the battery’s negative and positive plates in order for stored elections to flow from the battery. During battery use, electrons are released by a chemical reaction between the lead plates and sulfate ions (a component of the electrolyte). Those electrons flow from the negative terminal (thus, lead-sulfate appears on the negative plates), through the attached equipment, then back to the battery’s positive terminal where they are absorbed by a chemical reaction (thus, lead-sulfate appears on the positive plates). Fortunately, fresh lead-sulfate is soft and can be removed from the negative and positive plates when recharging of the battery. More specifically, the chemical reaction is reversed during the recharging process, and therefore rids the plates of soft lead-sulfate. However, see the FAQ for “What is lead-sulfation?”.

‣ What is lead-sulfation?

Lead-sulfation occurs when soft lead-sulfate crystals are not adequately reconverted back to their component parts (i.e., lead and sulfate ions) in a timely manner. The result is that soft lead-sulfate hardens into irreversible lead-sulfation. Typically, this occurs if a battery is drained, then not recharged within a sufficient amount of time (noted below). Once hardened, lead-sulfation is highly resistant to chemical reversal during the recharging process. As such, lead-sulfation is permanent and cannot be reversed. Therefore, the battery’s performance is permanently degraded, and its operation life is reduced. Furthermore, those hardened crystals will continue to grow (a process known as “Ostwald Ripening”). This growth thereby covers additional active areas of the plates, which exacerbates the situation by deactivating those areas, thus further degrading battery performance and life. For reference, if a Hawker® battery is shallow discharged [e.g., no more than 40% DoD (Depth of Discharge)], it should be fully recharged within 30 days. However, if a Hawker® battery is deeply discharged (e.g., more than 40% DoD), it should be fully recharged within 2 days. For a detailed explanation of DoD, see the FAQ for “What is Depth of Discharge (DoD)?”.

‣ What is AGM?

AGM is an acronym for Absorbed Glass Mat. It’s an absorbent fiberglass mesh material, and within an AGM battery, this fiberglass matting is layered between the negative (-) and positive (+) lead plates. AGM serves two purposes: (1) it acts a separator between the negative (-) and positive (-) plates to prevent short-circuiting, and (2) the matted material fully absorbs the electrolyte (allowing no free-flowing liquid), thereby making the battery essentially spill-proof. As a result of the tightly packed compression between the AGM material, the lead plates, and the cell walls of the battery…AGM batteries are the most vibration and impact resistant lead-acid batteries available today. Furthermore, since AGM batteries are virtually the same nominal voltage as flooded-cell (a.k.a., wet) and gel-cell batteries, they can be used as drop-in replacements, yet provide more power, greater Depth of Discharge (DoD), and longer life. For more information, it’s recommended that you visit the Hawker® Video Vault and view the training video entitled, “Benefits of AGM Batteries”.

‣ What is VRLA?

VRLA is an acronym for Valve-Regulated Lead-Acid. For example, the Hawker® ARMASAFE™ Plus 6TAGM battery is a lead-acid battery (in fact, the battery’s plates are 99.99% pure lead), and each of its six nominal 2-volt cells has an independent pressure-relief valve to regulate any potential off-gassing (though, under proper normal use, off-gassing is a rare occurrence with Hawker® AGM batteries). The six nominal 2-volt cells are connected in series configuration within the battery case to produce a nominal 12-volt battery.

‣ What is TPPL?

TPPL is an acronym for Thin Plate Pure Lead. For example, typical flooded-cell SLI (Starting, Lighting, and Ignition/Instrumentation) batteries use thicker plates that are formed from a lead-calcium or lead-antimony alloy. However, Hawker® batteries use thinner plates (up to twice as many plates than are found in a same-sized flooded-cell battery), and Hawker® battery plates are 99.99% pure lead. More plates equates to more active-material surface area. Pure lead paired with greater surface area equates to more power, deeper discharge capability, longer shelf-life, and longer expected operational life. Note: Some AGM batteries are made with lead-calcium vs. TPPL plates, as such they are up to 10 times more prone to venting gases (hydrogen, oxygen, and hydrogen sulfide) during normal charging, which results in lower expected operational life and lesser performance than TPPL AGM batteries.

‣ What is an SLI battery?

SLI batteries are designed to provide the initial short-burst of energy to power a vehicle’s starter, lights, and instruments (SLI). While SLI batteries are good at providing short bursts of current, they are not designed to provide long term energy (Capacity). In fact, after engine start, the vehicle’s alternator generates most (if not all) of the energy to power the lights, instruments, and accessories, as well as recharge the battery. SLI batteries are commonly found in the average personal vehicle. However, an SLI battery is not designed to be drained to more than a 40% Depth of Discharge (DoD)…meaning it should always retain at least 60% of its energy (known as a 60% State of Charge or SOC)…else risking internal damage to the battery. Normally, when choosing an SLI battery the CA and CCA ratings are the most important ratings (see definitions below).

‣ What is a Deep-Cycle battery?

A deep-cycle battery (commonly referred to as a “marine” battery) can not only perform the duties of an SLI battery, but it also has the power to provide sustained energy with the engine off. Deep-cycle batteries are designed to be regularly discharged of their full Capacity. Often, AGM deep-cycle batteries are used to power communications equipment, lights, sirens, winches, tactical equipment, etc. on vehicles when the engine is off…or to power trolling motors on boats. They have the ability to be drained below 40% DoD…down to 100% DoD…and still be recovered (recharged). Normally, when choosing a deep-cycle battery the Capacity rating is the most important rating. However, if the battery will also be used for starting, then the CA and CCA ratings are equally important (see definitions below).

‣ What is meant by improperly mixing batteries?

Generally, only batteries that are the same model from the same battery manufacturer and about the same age should be wired in parallel, series, or series-parallel configurations. Standard vehicle batteries are available in many different sizes (6T, G31, G34, etc.), types (flooded/wet, gel, AGM), chemistries (pure lead, lead-calcium, lead-antimony), and nominal voltages (6-, 8-, 12-, and 24-volts). As such, they have different characteristics in terms of fitment, electrochemical properties, electrical capabilities, and hazard classification. For example, two batteries with similar physical dimensions may have different top-off Open Circuit Voltages (OCV), Cold Cranking Amp (CCA) ratings, as well as Capacity ratings. Furthermore, they may have different charge/discharge profiles, cycling capabilities, Usable Reserve ratings, and internal resistances (see definitions below).

‣ What are the effects of improperly mixing batteries?

Due to potential differences in charge/discharge characteristics, one or more batteries may become overcharged and/or one or more battery may be left undercharged. As a result, individual battery State of Charge (SOC) imbalance occurs which may result in safety and/or performance issues. In the case of an overcharge, this may create a potentially dangerous situation due to extreme heat and/or excessive off-gassing. Furthermore, either undercharging or overcharging batteries will ultimately shorten battery pack life. Also, since the batteries may become damaged, normally the manufacturer’s warranty will be voided.

‣ Is there a military Technical Bulletin (TB) for the care and maintenance of VRLA AGM batteries, like the Hawker® ARMASAFE™ Plus 6TAGM battery?

Yes. TB 9-6140-252-13, “Recharging procedures for Automotive Valve Regulated Lead-Acid Batteries” dated 31 January, 2012.

‣ What is MIL-PRF-32143?

A MIL-PRF is a United States military performance specification. The Hawker® ARMASAFE™ Plus 6TAGM battery is manufactured to meet or exceed the requirements of MIL-PRF-32143C (“C” represents the current revision).

‣ What is Voltage (V)?

Specifically, Voltage (V) is a unit of measurement for electromotive force. The electromotive force is caused by a difference in charge between two points (e.g., between the battery’s positive (+) and negative (-) battery terminals). Colloquially, voltage is known as electrical pressure; it’s the force that moves electrons through circuitry to provide power.

‣ What is Nominal Voltage?

Typical vehicle batteries are called 12-volt batteries, but that’s just a generic term. Actually, different types of lead-acid batteries have different “top-off” voltages. In fact, standard 12-volt flooded-cell batteries typically measure 12.6 volts Open Circuit Voltage OCV) and AGM batteries typically measure 12.9 volts (OCV) when the batteries are fully charged.

‣ What is Open Circuit Voltage (OCV)?

For a single battery, Open Circuit Voltage (OCV) is the measurement of voltage between its positive (+) and negative (-) battery terminals when there is no load on the battery. In other words, the battery is at a state of rest, neither providing power nor receiving a charge. Since a lead-acid battery is a direct current (DC) power source, measurement is usually conducted with either a DC voltmeter or a multimeter with a DC voltmeter setting.

‣ What is Closed Circuit Voltage (CCV)?

For a single battery, Closed Circuit Voltage (CCV), commonly known as “load” voltage, is the measurement of voltage between its positive (+) and negative (-) battery terminals when there is a load on the battery. In other words, the battery is providing power (or is receiving a charge). For battery-powered systems (direct current), measurement is usually conducted with either a DC voltmeter or a multimeter with a DC voltmeter setting.

‣ What is a Load?

A load is the amount of current being drawn from the battery, measured in amps (e.g., a 25-amp load.) While engine start is typically the greatest single load placed a battery…headlights, instrumentation, fans, radios, etc. all place additional loads on the battery…especially when the engine is off (as the alternator is no longer providing power).

‣ What is Current?

Electric current is the rate of flow of electric charge (specifically, electrons) through a specific point in a closed circuit loop. Current flow is measured in amps.

‣ What is an Amp?

An Amp (or Ampere) is a unit of measurement for electrical current (a.k.a., flow). It’s equivalent to the combined charge of 6.24 quintillion (that’s 6.24 billion billion) negatively-charged electrons passing through a single point in one second. When moved by voltage (electrical pressure) through circuitry, electrons are what power equipment. For battery-powered systems (direct current), measurement is usually conducted with either a DC ammeter or a multimeter with a DC ammeter setting.

‣ What is Resistance?

Resistance is a unit of measurement of an object’s (e.g., copper, rubber, etc.) opposition to the flow of electrical current in a direct current (DC) circuit. Note that in alternating current (AC) circuits the equivalent is called “impedance”. The measurement for both is expressed in ohms. For both AC- and DC-powered systems, measurement is usually conducted with either an ohmmeter or a multimeter with an ohmmeter setting.

‣ What is Internal Resistance?

Internal resistance is the level of electrical resistance within a battery. For example, the internal resistance of a new Hawker® ARMASAFE™ Plus 6TAGM battery is a relatively low 0.0017 ohms, while a new 6TMF battery is 0.009 ohms (that’s 5.3 times higher resistance). Furthermore, a dead battery’s internal resistance may be 0.645 ohms…which is 380 times greater!

‣ What are Cranking Amps (CA)?

Cranking Amps (CA) is a standard battery industry rating referring to the cranking power that a fully-charged battery has available to start an engine when the battery is at 32°F. The rating specifically refers to the amount of amps that a nominal 12-volt battery can deliver at 32°F (0°C) for 30 seconds while still maintaining a battery voltage of at least 7.2 volts (that’s 1.2 volts per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has a CA rating of 1550 amps, while the same-sized flooded-cell 6TMF battery has a much lower CA rating of 900 amps. Bottom line: The more CAs the battery has, the more power it has to start an engine in all but very cold climates. For very cold climates, refer to CCA. Note: A battery’s CA rating will be higher than its CCA rating.

‣ What are Marine Cranking Amps (MCA)?

Marine Cranking Amps (MCA) is a standard battery industry rating typically found on marine (boat) batteries. MCA and Cranking Amps (CA) are synonymous.

‣ What are Cold Cranking Amps (CCA)?

Cold Cranking Amps (CCA) is a standard battery industry rating referring to the cranking power that a fully-charged battery has available to start an engine when the battery is at 0°F. The rating specifically refers to the amount of amps that a nominal 12-volt battery can deliver at 0°F (-18°C) for 30 seconds while still maintaining a battery voltage of at least 7.2 volts (that’s 1.2 volt per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has a CCA rating of 1225 amps, while the same-sized flooded-cell 6TMF battery has a much lower CCA rating of 725 amps. Bottom line: The more CCAs the battery has, the more power it has to start an engine in very cold climates. Note: A battery’s CCA rating will be lower than its CA rating.

‣ What are Extreme Cold Cranking Amps (ECCA)?

Extreme Cold Cranking Amps (ECCA) is a non-standard battery industry rating referring to the cranking power that a fully-charged battery has available to start an engine when the battery is at -40oF. The rating specifically refers to the amount of amps that a nominal 12-volt battery can deliver at -40oF (-40oC) for 30 seconds while still maintaining a battery voltage of at least 7.2 volts (that’s 1.2 volt per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has an ECCA rating of 500 amps, while the same-sized flooded-cell 6TMF battery has a much lower ECCA rating of 350 amps. Bottom line: The more ECCAs the battery has, the more power it has to start an engine in extremely cold climates. Note: A battery’s ECCA rating will be lower than its CCA rating.

‣ What are Hot Cranking Amps (HCA)?

Hot Cranking Amps (HCA) is a standard battery industry rating referring to the cranking power that a fully-charged battery has available to start an engine when the battery is at 80°F. The rating specifically refers to the amount of amps that a nominal 12-volt battery can deliver at 80°F (27°C) for 30 seconds while still maintaining a battery voltage of at least 7.2 volts (that’s 1.2 volt per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has an HCA rating of 1730 amps.

‣ What are Pulse Hot Cranking Amps (PHCA)?

Pulse Hot Cranking Amps (PHCA) is a non-standard battery industry rating referring to a 5 second burst of cranking power that a fully-charged battery can provide to start an engine when the battery is at 80°F. The non-standard rating specifically refers to the amount of amps that a nominal 12-volt battery can deliver at 80°F (27°C) for 5 seconds while still maintaining a battery voltage of at least 7.2 volts (that’s 1.2 volt per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has a PHCA rating of 2250 amps. The 5 second cranking duration represents the average time to start a normal engine.

‣ What is Reserve Capacity (RC)?

Reserve Capacity (RC) is a standard battery industry rating referring to the length of time the battery can maintain a typical vehicle’s electrical needs in the event of alternator failure. The rating specifically refers to the number of minutes a nominal 12-volt battery can deliver a constant 25 amps at 80° F (27°C) while maintaining a voltage of at least 10.5 volts (that’s 1.75 volts per cell). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has an RC rating of 240 minutes, while the same-sized flooded-cell 6TMF battery has a lower RC rating of 200 minutes.

‣ What is an Amp-hour (Ah)?

An Amp-hour (Ah, or ampere-hour) is equal to providing 1 amp of current for 1 hour. For example, 500 mAh battery will provide 500 milliamps of current for 1 hour. An 80.7 Ah battery will provide 80.7 amps of current for 1 hour (assuming a C1 Rate, see C-rate below).

‣ What is C-rate?

The C-rate is the constant rate at which a battery is being fully discharged relative to its maximum Capacity. For example, a C-rate of C1 is the equivalent to a battery being fully discharged in 1 hour at a specific constant load (or current). A C20 rate is the equivalent to a battery being fully discharged in 20 hours at a specific constant load (or current). See a detailed example in the “What is Capacity?” FAQ.

‣ What is Capacity?

Capacity represents the maximum amount of current stored in a battery in terms of amp-hours (or ampere-hours; Ah) when discharged at a specific constant rate (known as C-rate). For example, the Hawker® ARMASAFE™ Plus 6TAGM battery has a Capacity of 120 Ah at a C20 rate [denoted as 120 Ah (C20)]. So, divide 120 by 20, resulting in a continuous 6 amps of constant current throughout the 20-hour period, at the end of which the battery will be drained to 10.5 volts (that’s 1.75 volts per cell) and be considered fully discharged. Be cautious when comparing different batteries by their Capacity ratings to ensure that the C-rate specifications are identical, since Capacity is affected by the C-rate, and the Capacity/C-rate relationship is non-linear. For example, at a C5 rate the Hawker® ARMASAFE™ Plus 6TAGM battery has a Capacity of 102.5 Ah, which is 20.5 amps for 5 hours. At a C1 rate it can provide 80.7 Ah, which is 80.7 amps for 1 hour. As is shown, at faster discharge rates, the battery provides fewer total amp-hours.

‣ What is Depth of Discharge (DoD)?

Depth of Discharge (DoD) is the degree to which a lead-acid battery has been discharged. It’s usually stated as a percentage of the battery’s rated amp-hour (Ah) Capacity. For example, the Hawker® ARMASAFE™ Plus 6TAGM battery is rated at 120 Ah (C20). However, if 12 Ah are drained from the battery, it’s considered to be at 10% DoD. Inversely, the battery is considered to have a 90% State of Charge (SOC).

‣ What is State of Charge (SoC)?

The State of Charge (SoC) of a battery is the ratio of its real-time (actual) capacity relative to its ideal (maximum or “rated”) capacity. Put simply, SoC is an expression of a battery’s actual level of charge vs. its maximum possible charge potential. SoC is reported as a percentage from 0-100% and is inversely proportional to DoD (e.g., as SoC increases, DoD decreases by the same amount, and vice-versa). Though there are numerous techniques for measuring SoC, for lead-acid batteries the SoC is virtually linear to and proportional with the battery’s OCV reading (measurement). And, since measuring SoC by OCV testing (i.e., by using either a voltmeter or multimeter) is simple and fairly accurate for lead-acid batteries, it is the technique most often used by mechanics. For example, when a Hawker® ARMASAFE™ Plus 6TAGM battery is at or above 12.9V OCV, it is considered to have a 100% SoC (full charge). Likewise, at 12.2V OCV it has a 50% SoC (half charge). And, at 11.5V OCV it has a 0% SoC (no charge). When a battery is at 0% SoC, it virtually has little to no remaining stored amperage (neither CCAs nor Ah). That said, it’s important to mention that although a battery may have a high SoC, it can still have a low State of Health (SoH). In other words, while an unhealthy, but recharged, battery may still achieve the rated top-off voltage (e.g., 12.9V OCV), it may have nearly zero amps. SoC is a temporary condition that is affected by simply exercising the battery, either by charging or discharging. As such, a battery’s SoH is a much more accurate depiction of its actual capabilities (e.g., CCAs & Ah). Lastly, if a used Hawker® battery cannot be recharged to at least 12.65V OCV, it should be replaced.

‣ What is State of Health (SoH)?

The State of Health (SoH) of a battery refers to the remaining (actual) quantity of active material within the battery relative to its ideal (full) quantity of active material. To clarify, as batteries age (and/or due to excessive discharge and/or by allowing a battery to remain in a discharged state), some (or all) of the active material within the battery will become inactive (i.e., permanent and irreversible lead-sulfation), thereby reducing (or eliminating) a battery’s available Ah and CCAs. SoH is reported as a percentage from 0-100%. Though there are numerous techniques for measuring SoH, for lead-acid batteries it is typically measured by performing a capacity, load, or conductance test. For example, a Hawker® ARMASAFE™ Plus 6TAGM battery with a 100% SoH should provide a minimum of 120 Ah (C20), remain at or above 11.5V CCV during a load test, and/or have a minimum of 1225 CCAs. When the battery is at a 90% SoH, it should provide a minimum of 108 Ah (C20), remain at or above 11.4V CCV during a load test, and/or have a minimum of 1103 CCAs. And, at an 80% SoH, it should provide a minimum of 96 Ah (C20), remain at or above 11.0V CCV during a load test, and/or have a minimum of 980 CCAs. SoH is a permanent condition that is virtually in one direction (from the full health of a new battery down to the end of the operational life of a used battery). As an industry standard, if a fully–charged battery cannot achieve at least an 80% SoH, it should be replaced.

‣ What is Usable Reserve?

Usable Reserve is commonly referred to as: “How much can a battery be discharged and still have enough CCAs to start a vehicle?” However, since every vehicle has a different starting (load) profile, Usable Reserve is the lowest Depth of Discharge (DoD) state a battery can be, yet still be able to provide up to 10 seconds the of battery’s rated CCAs. Usable Reserve is expressed as a percentage of (DoD). For example, the standard flooded-cell 6TMF battery has a Usable Reserve of 30% DoD, whereas the Hawker® ARMASAFE™ Plus 6TAGM battery has a Usable Reserve at a much deeper 70% DoD. So, a 70% drained (36 Ah remaining) Hawker® ARMASAFE™ Plus battery can still deliver 1225 amps at 0°F (-18°C) for 10 seconds, which is usually ample time to start a vehicle.

‣ What is Cycle Life?

For lead-acid batteries, one cycle is equal to discharging a fully-charged battery until it reaches a 40% Depth of Discharge (DoD), then fully recharging it back to its rated Capacity. Since the Hawker® ARMASAFE™ Plus 6TAGM battery has a rated Capacity of 120 Ah (C20), a 40% DoD is achieved when the battery has had 48 Ah drained (inversely, 72 Ah remaining). Cycle Life is the number of cycles a battery can perform before it fails to fully recharge (back to its full rated Capacity). For example, the flooded-cell 6TMF battery has a cycle life of 235 cycles. MIL-PRF-32143C requires the 6TAGM battery to be able to perform 360 cycles, however, the Hawker® ARMASAFE™ Plus 6TAGM battery can usually provide 900+ cycles.

‣ What is Deep-Cycle Life?

For lead-acid batteries, one deep-cycle is equal to discharging a fully-charged battery until it reaches a 100% Depth of Discharge (DoD), then fully recharging it back to its rated Capacity. Since the Hawker® ARMASAFE™ Plus 6TAGM battery has a rated Capacity of 120 Ah (C20), 100% DoD is achieved when the battery has had 120 Ah drained (inversely, 0 Ah remaining). Deep-Cycle Life is the number of deep-cycles a battery can perform before it fails to fully recharge (back to its full rated Capacity). For example, the flooded-cell 6TMF battery is not rated for deep-cycling. MIL-PRF-32143C requires the 6TAGM battery to be able to perform 120 deep-cycles, however, the Hawker® ARMASAFE™ Plus 6TAGM battery can usually provide 180+ deep-cycles.

‣ What is Shelf-Life?

Generically, shelf-life is the amount of time a new battery can be stored, under specified conditions, before it requires recharge. Specifically, it’s is the length of time, under specified conditions, that a new battery can be stored such that it retains its guaranteed Capacity. The shelf-life of a new 6TMF battery is 3 months when stored at 77° F (25°C). MIL-PRF-32143C requires a new 6TAGM to have a 24 month shelf-life, however, new Hawker® batteries can usually provide up to 30 months of shelf-life when stored at 77° F (25°C) or cooler. Note: Use of an appropriate preventive maintenance charger (a.k.a., float charger, trickle charger, etc.) can extend the shelf-life by up to a factor of 5.

‣ What is Self-Discharge?

A phenomenon in batteries in which chemical reactions within the battery reduce its charge. This can happen even when the battery’s terminals are not connected to a vehicle or piece of equipment. Self-discharge decreases both shelf-life and the expected operational life of batteries. Note: Use of an appropriate preventive maintenance charger (a.k.a., float charger, trickle charger, etc.) can help to counter self-discharge, thereby increasing battery life.

‣ What is Parasitic Drain?

A parasitic drain is an unintentional (and undesirable) load on a battery. This is especially important if the engine is off, as these parasitic loads can drain the battery. Many tactical and combat vehicles have communications equipment, a BFT, a DAGR, thermal and/or infrared sighting systems, as well as other tactical equipment that, if installed improperly, will drain the vehicle’s batteries. If experiencing constant “dead” batteries, the first places to look are the accessories that might be causing excessive parasitic drain.

‣ How can I diagnose the source of a parasitic load or drain?

Here’s a recommended diagnostic method to locate the offending culprit:

1. Turn the engine off and allow about 2 minutes (normally) for the vehicle to enter into sleep mode.

2. Place a DC ammeter clamp around either the negative or positive battery cable. Check for any measured reading. Typically, during sleep mode there may be a 30-50 milliamp load (though, possibly up to 200 milliamps) to support onboard systems (e.g., radios, GPS systems, memory seats, etc.). These planned loads are usually referred to as “key-off” loads or “sleep current”. Check the vehicle’s TM or repair manual for the specification. If the amp load is greater than the spec, you have a parasitic load.

3. For conventional vehicles, begin by pulling individual fuses noting any significant drop in amperage, immediately reinstall each fuse if there is no drop. Once you identify the circuit or circuits causing the parasitic load, refer to the vehicle’s wiring diagram to determine the components connected to that circuit. Inspect each component and associated wiring for signs of damage, corrosion, or malfunction. For many military vehicles that are designed without fuse boxes, place an ammeter either fore or aft of an individual LRU (line-replaceable unit) or LRM (line-replaceable module) to observe for current flow. Continue with each LRU/LRM until a parasitic load is detected.

4. For conventional vehicles, you may need to perform additional testing on each component, such as checking for short circuits, proper wiring, or utilization of advanced diagnostic tools. For military vehicles, consult the vehicle’s TM for repair or replacement.

‣ Are Battery Maintenance and Recovery Training (BMRT) videos available?

Yes. Visit the Hawker® Video Vault to view the on-demand Hawker® Helpdesk video training series. These videos are free to view and accessible to everyone.

‣ What do the labels and markings on the Hawker® ARMASAFE™ Plus 6TAGM battery indicate?

It’s recommended that you visit the Hawker® Video Vault and view the training video entitled, “Battery Labels & Markings: Hawker® ARMASAFE™ Plus”.

‣ Does temperature affect batteries?

Yes. Battery Capacity is reduced as temperature goes down and increased as temperature goes up. This is why a vehicle battery dies on a cold winter morning, even though it worked fine during the previous warm afternoon. Also, through self-discharge, the typical flooded-cell SLI battery loses about 3% of its Capacity per month when kept at 77°F (25°C), whereas the Hawker® ARMASAFE™ Plus 6TAGM battery loses much less at about 1 to 1 1/2 % per month. However, for every 15°F (8.3°C) increase in temperature, the self-discharge rate doubles from its previous rate. So, at 92°F (33.3°C), the self-discharge rate for flooded-cell is 6%, and for a typical AGM it is 2-3%. At 107°F (41.6°C), the self-discharge rate for flooded-cell is 12%, and for a typical AGM it is 4-6%. Note: The Hawker® ARMASAFE™ Plus 6TAGM battery is tested by EnerSys® and the US Government (IAW MIL-PRF-32143C) to perform at extreme hot and cold temperatures from -40°F to +176°F (-40°C to +80°C).

‣ What are the eight most common causes of premature lead-acid battery failure in the military?

- Insufficient vehicle run-time. Engine cranking requires energy. For example, a light tactical vehicle may require 500 CCAs, whereas a heavy combat vehicle may require 2000 CCAs. If the engine is constantly started, then immediately stopped, then the alternator will not have enough time to fully recharge the battery.

- Battery self-discharge. A battery’s State of Charge (SOC) should be routinely monitored (approximately every 3 months), especially if it’s stored or installed on a vehicle or piece of equipment that is left unused. If the battery is not fully charged, recharge it back to its full rated Capacity. It is highly recommended that fully-charged batteries in storage be placed on an appropriate preventive maintenance charger (a.k.a., float charger, trickle charger, etc.) until they are needed. If the battery is in a vehicle or other equipment that is not used on a regular basis, periodically check the battery’s Open Circuit Voltage (OCV) and recharge it if the voltage has dropped. For a Hawker® battery, it is highly recommended that the battery be recharged when its OCV drops to no less than 12.65 volts.

- Temperature induced failure. As mentioned above, increased battery temperatures cause an increase the battery’s self-discharge rate. If the battery is allowed to drain, this will result in decreased shelf-life and decreased expected operational life.

- Dirty battery terminals and/or case. Dirty battery terminals increase resistance and make the vehicle’s electrical system work harder. Furthermore, if enough conductive dirt, debris, or corrosion creates a connection between the negative (-) and positive (+) battery terminals, a surface discharge can occur across the top of the battery case, thereby draining the battery.

- Intermixing of batteries of different size, type, chemistries, voltages, or from different manufacturers. Also, identical batteries of different ages. Different batteries may have different voltage and CCA ratings. Additionally, they may accept voltage at different rates, gas at different temperatures, and (based on battery chemistry) may have different internal resistances. Furthermore, even new and old batteries of the same type and size from the same manufacturer may have different internal resistances (caused by normal plate sulfation over time as an older battery ages).

- Parasitic drain and/or leaving loads on when the vehicle is not is use. If a vehicle has a “master” power switch, it’s advisable to turn it to the “off” position when the vehicle and its equipment are not in use. If the vehicle is off, but its equipment is still in use, it’s highly beneficial to have a low voltage load shedding/reduction program in place to protect batteries from over-discharge (assuming the vehicle has a battery management system). Under load shedding, when battery’s (or battery pack’s) voltage drops to a certain level, non-critical items (as assigned by the user) are powered “off” and only mission-essential equipment remain “on”. For example, load shedding in a nominal 24-volt system (note that fully-charged Hawker® batteries actually provide 25.5 volts when wired in series and series-parallel configurations) typically occurs when the voltage drops to about 23 volts (CCV), this results in increasing battery life to power essential loads only. Since there are fewer loads on the battery pack, the voltage will then increase due to the lower amount of load being placed on the battery pack. Note, however, that once the battery pack again falls to 23 volts (CCV), all power will cease, therefore all equipment will be powered “off”.

- Faulty electrical system. Verify that the vehicle’s wiring and accessories are not shorting out (a.k.a., short circuit). And, when using AGM batteries, ensure that the voltage regulator only allows passage of no more than 15 volts toward a single battery or batteries wired in a nominal 12-volt parallel configuration and no more than 30 volts toward batteries wired in a nominal 24-volt series or a nominal 24-volt series-parallel configuration.

- Physical damage. Do not stack batteries more than two high. Do not stack a battery directly on top of another battery, unless the bottom battery is in the manufacturer’s original shipping box. If the manufacturer’s original shipping box is not available, place non-conductive dunnage material on the top of the bottom battery such that it rises at least ¼ inch above that battery’s terminals, then stack the second battery on the dunnage (insuring that it is not resting on the bottom battery’s terminals). By keeping batteries off the ground/floor, it reduces the likelihood of damage caused by rolling stock (from such items at hand trucks, pallet jacks, forklifts, etc.). Furthermore, due to potential temperature transfer, by keeping batteries off a cold ground/floor it reduces the likelihood of freezing a battery’ Likewise, by keeping batteries off a hot ground/floor it reduces the likelihood of increasing the battery’s self-discharge rate (thereby reducing both shelf-life and expected operational life).

‣ Do Hawker® batteries have a warranty?

Yes, Hawker® batteries have a 36-month Limited Warranty.

‣ What are the air, land, and sea shipping requirements for Hawker® batteries?

In accordance with various shipping regulations (listed below), Hawker® batteries are classified and certified as non-spillable (UN2800). As such, they are exempt from hazardous goods transportation requirements for air, land, and sea when:

- if uninstalled:

- the battery’s terminals are protected against short circuiting (e.g., the manufacturer’s original plastic battery terminal covers are installed), and

- the battery is securely packed in strong outer packagings (e.g., the manufacturer’s original shipping box) or secured to skids or pallets capable of withstanding the shocks normally incident to transportation, and

- the outer packaging must be plainly and durably marked “NON-SPILLABLE” or “NON-SPILLABLE BATTERY”.

- if installed:

- the battery must be securely fastened in the equipment or vehicle’s battery holder, and

- the battery must be prevented from unintentionally activating the equipment or vehicle, and

- the equipment or vehicle’s outer packaging must be plainly and durably marked “NON-SPILLABLE” or “NON-SPILLABLE BATTERY”. However, the requirement to mark the outer packaging does not apply when the battery is installed in a piece of equipment or vehicle that is transported unpackaged.

See EnerSys® publication “Requirements for Shipping Nonspillable Batteries via Expedited Carrier” for additional recommendations.

If authoritative guidance is required regarding either the definition/classification of a “non-spillable” battery or the shipping requirements for “non-spillable” batteries, refer to:

- U.S. Department of Transportation: See 49 CFR Section 173.159, paragraph (f) and 49 CFR Section 173.159a

- International Civil Aviation Organization (ICAO): See Document 9284 – Technical Instructions for the Safe Transport of Dangerous Goods by Air, Special Provision A67 and Packing Instruction 872

- International Air Transport Association (IATA) Dangerous Goods Regulations: See Special Provision A67 and Packing Instruction 872

- International Maritime Dangerous Goods (IMDG) Code: UN Number 2800, Class 8 (batteries, wet, non-spillable, electric storage). See Special Provision 238 and Packaging Instruction P003

‣ I have technical questions and/or I want to order, who do I contact?

Hawker® battery Field Support Representatives (FSR) are available to answer your technical questions, provide product quotes, and assist in the ordering process. Simply contact us on the web or call the Hawker® Hotline at 877.485.1472.

‣ What is Hawker® Headlines?

Hawker® Headlines is a free digital quarterly technical newsletter. Want to be added to the distribution list, simply contact us on the web or call the Hawker® Hotline at 877.485.1472.

‣ What is the proper way to inspect a new or used Hawker® ARMASAFE™ Plus 6TAGM battery?

Before installing, it’s recommended that you visit the Hawker® Video Vault and view the training video entitled, “Battery Inspection: Hawker® ARMASAFE™ Plus”. Also, refer to TB 9-6140-252-13.

‣ Does a battery’s Open Circuit Voltage (OCV) singularly indicate its state of health?

No. A battery can be at or above the battery’s rated voltage, yet still not meet the battery’s CA, CCA, or Capacity ratings. In other words, it’s possible to recharge a deeply-drained, deeply-sulfated nominal 12-volt battery whose Open Circuit Voltage measures 5 volts (though rated at 12.9 volts and 1225 CCAs), and while at the end of charge cycle the battery’s OCV reaches the 12.9 volt rating, it is only capable of providing 10 CCAs. See below for proper testing methods.

‣ What is the proper way to test a new or used Hawker® ARMASAFE™ Plus 6TAGM battery?

Before installing, it’s recommended that you visit the Hawker® Video Vault and view the following training videos:

- “Battery Testing: Multimeters”,

- “Battery Testing: Mechanics Load Testers”

- “Battery Testing: Conductance Analyzers”

- “Battery Testing: Parallel, Series, and Series-Parallel”

Also, refer to TB 9-6140-252-13.

‣ What is the recommended charger output voltage when applying a fast or recovery (corrective maintenance) charge on a Hawker® battery?

Under normal conditions, when fast or recovery charging a single nominal 12-volt Hawker® battery, the charger should have an output voltage between 14.4 to 15.0 VDC. The optimal constant voltage is 14.7 VDC when the battery’s temperature is at 77o F (25o C). When the battery’s temperature is between 68o F (20o C) and 86o F (30o C), it’s not recommended to use a charger (or alternator) whose output voltage could exceed 15.0 VDC, nor if the output voltage is less than 14.15 VDC. If fast or recovering charging at higher or lower battery temperatures, contact us for more detailed information. However, if two or more batteries are wired together to form a nominal 24-volt series or series-parallel string , then the charger should have an output voltage between 28.5 to 30.0 VDC. The optimal constant voltage is 28.8 VDC when the batteries’ temperatures at 77o F (25o C). When the batteries’ temperatures are between 68o F (20o C) and 86o F (30o C), for 24-volt strings, it’s not recommended to use a charger (or alternator) whose output voltage could exceed 30.0 VDC, nor if the output voltage is less than 28.30 VDC. Again, if fast or recovering charging at higher or lower battery temperatures, contact us for more detailed information.

‣ What is the recommended charger output amperage when applying a fast or recovery (corrective maintenance) charge on a Hawker® battery?

Under normal conditions, when fast or recovery charging a single nominal 12-volt Hawker® battery or two batteries wired together to form a nominal 24-volt series string, it’s recommended that the charger have the ability to provide at least 10 amps or more. However, if two batteries are wired together to form a nominal 12-volt parallel string or four batteries are wired together to form a nominal 24-volt series-parallel string, then it’s recommended that the charger have the ability to provide at least 20 amps or more. Note that constant amperage chargers are not recommended for use with AGM batteries.

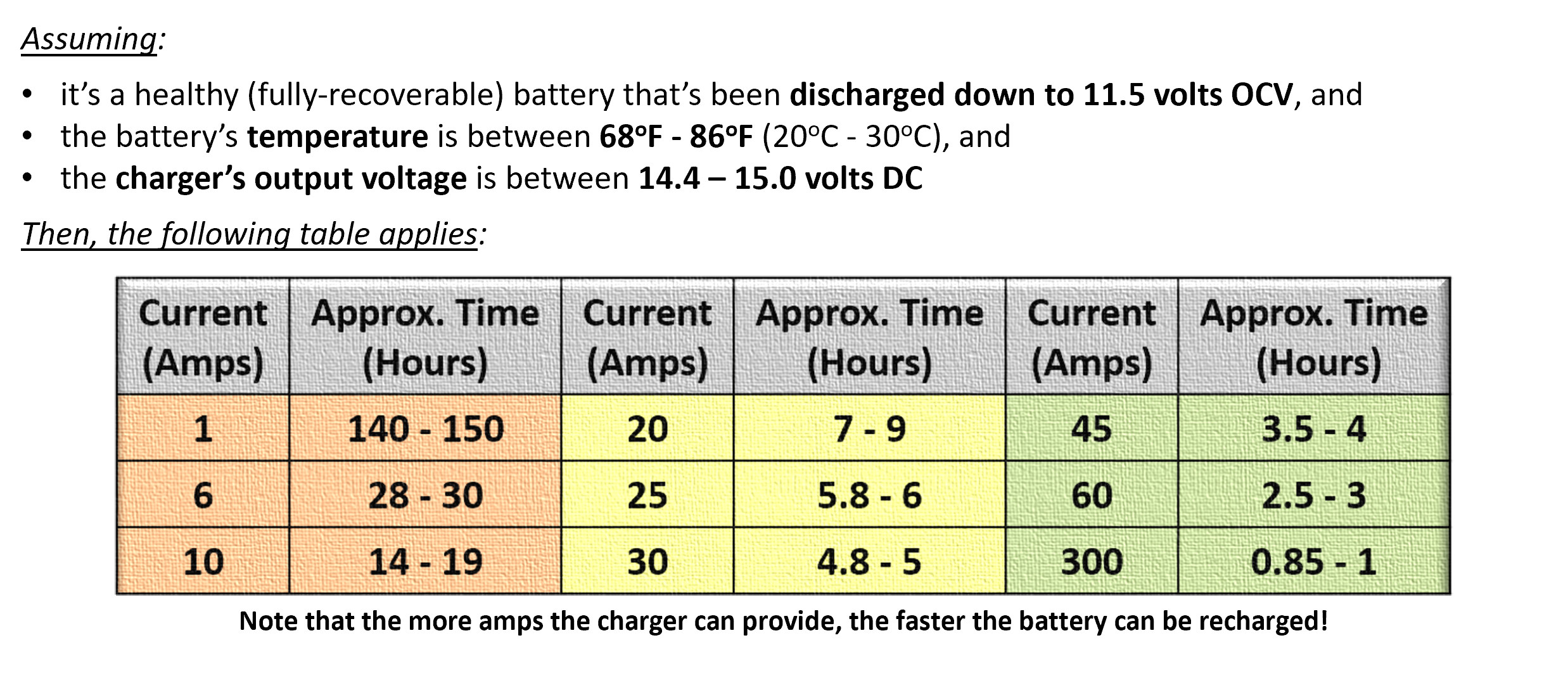

‣ About how much time should it take to recharge a drained Hawker® ARMASAFE™ Plus 6TAGM battery?

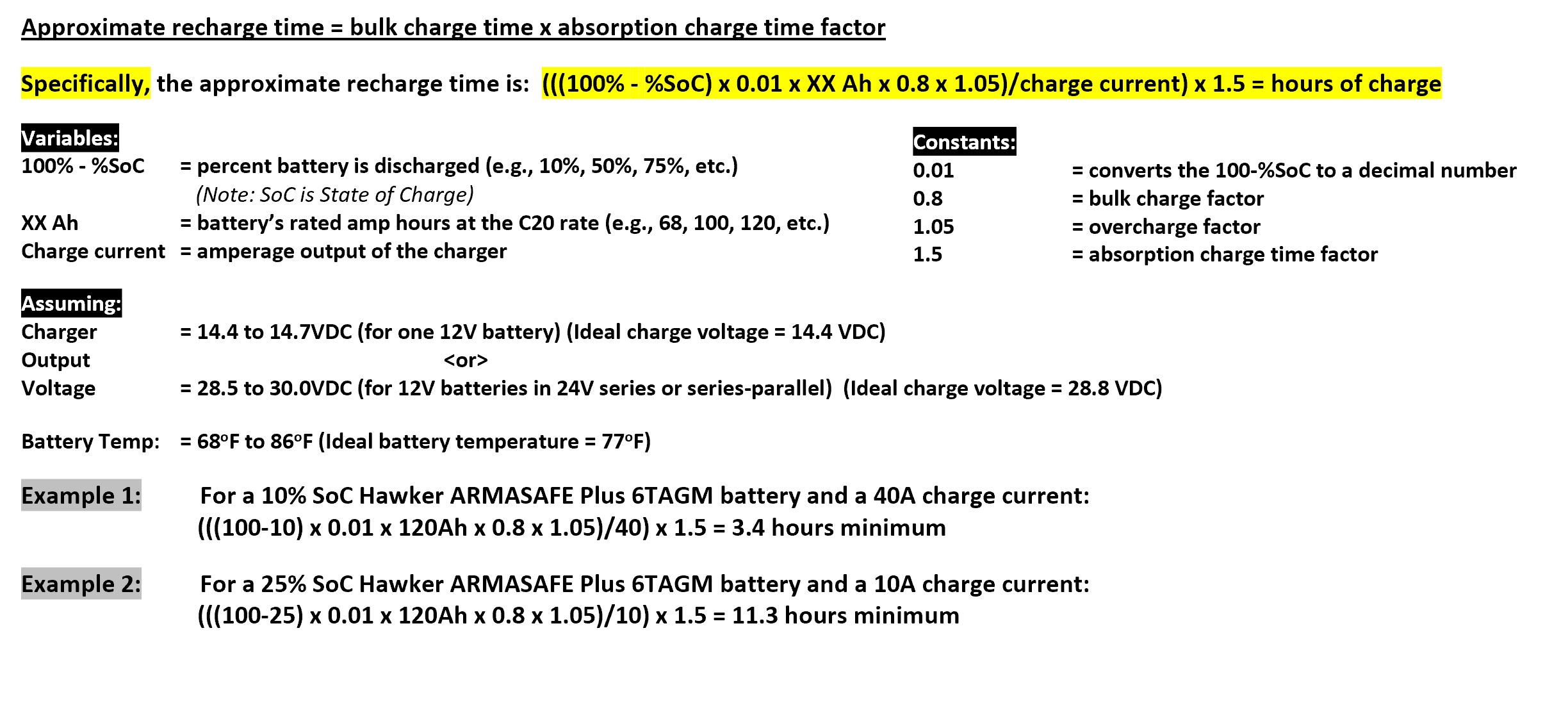

‣ Is there a calculation I can use to determine the “approximate recharge time” for pure-lead AGM batteries, like the Hawker® and Odyssey® brands?

‣ What is the recommended charger output voltage when applying a slow or float (preventive maintenance) charge on a Hawker® battery?

Under normal conditions, when slow or float charging a single nominal 12-volt Hawker® battery, the charger should have an output voltage between 13.5 to 14.1 VDC. The optimal constant voltage is 13.62 VDC when the battery’s temperature is at 77o F (25o C). However, if using a charger that has minor fluctuations (e.g., ±0.3 VDC) in output voltage, then a voltage of 13.8 VDC is recommend in order to ensure that the float voltage does not fall below the minimum 13.5 VDC. When the battery’s temperature is between 68o F (20o C) and 86o F (30o C), it’s not recommended to use a charger whose output voltage could exceed 14.1 VDC, nor if the output voltage is less than 13.5 VDC while in slow or float mode. If slow or float charging at higher or lower battery temperatures, contact us for more detailed information. However, if two or more batteries are wired together to form a nominal 24-volt series or series-parallel string, then the charger should have an output voltage between 27.0 to 28.2 VDC. The optimal constant voltage is 27.2 VDC when the batteries’ temperatures are at 77o F (25o C). However, if using a charger that has minor fluctuations (e.g., ±0.6 VDC) in output voltage, then a voltage of 27.6 VDC is recommend in order to ensure that the float voltage does not fall below the minimum 27.0 VDC. When the batteries’ temperatures are between 68o F (20o C) and 86o F (30o C), for 24-volt strings, it’s not recommended to use a charger whose output voltage could exceed 28.2 VDC, nor less than 27.0 VDC while in slow or float mode. Again, if slow or float charging at higher or lower battery temperatures, contact us for more detailed information.

‣ What is the recommended charger output amperage when applying a slow or float (preventive maintenance) charge on a Hawker® battery?

Assuming any battery connected to a float/trickle charger already has between a 70 to 100% State of Charge (SoC) and is capable of achieving between an 80 to 100% State of Health (SoH) upon recharge, the following applies. Under normal conditions, when slow or float charging a single nominal 12-volt Hawker® battery or two batteries wired together to form a nominal 24-volt series string, it’s recommended that the charger have the ability to provide between 1 to 2 amps. However, if two batteries are wired together to form a nominal 12-volt parallel string or four batteries are wired together to form a nominal 24-volt series-parallel string, then it’s recommended that the charger have the ability to provide between 2 to 4 amps. Of note, in some solar applications where the battery experiences routine, minor mAh (milliampere-hour) discharges (e.g., a 10 amp discharge for 1 second per hour), then it’s possible to use a charger that provides as low as 0.2 to 0.4 amps. Note that constant amperage chargers are not recommended for use with AGM batteries.

‣ What is the proper way to charge a new or used Hawker® ARMASAFE™ Plus 6TAGM battery individually?

Before charging, it’s recommended that you visit the Hawker® Video Vault and view the following training videos:

- “Battery Charging: Conventional Chargers”

- “Battery Charging: Advanced (Voltage Sensor) Chargers”

Also, refer to TB 9-6140-252-13.

‣ What is the proper way to charge new or used Hawker® ARMASAFE™ Plus 6TAGM batteries on a buss bar (12 VDC)?

Refer to TB 9-6140-252-13.

‣ What is the proper way to charge new or used Hawker® ARMASAFE™ Plus 6TAGM batteries through a NATO slave receptacle (24 VDC)?

Refer to TB 9-6140-252-13.

‣ What is the proper way to store a new or used Hawker® ARMASAFE™ Plus 6TAGM battery?

Before storing, it’s recommended that you visit the Hawker® Video Vault and view training video entitled, “Proper Battery Storage”.

‣ What is an NSN?

An NSN is a National Stock Number. NSNs are assigned to items (e.g., batteries, tires, lubricants, etc.) that are routinely procured, stocked, and issued within the federal supply system. When deemed necessary, federal supply system items are assigned an NSN by the Department of Defense’s (DoD) Defense Logistics Agency Logistics Information Service (DLIS). It’s normally a 13 digit code (e.g., the NSN for a 6TAGM battery that is “qualified” via MIL-PRF-32143C is: 6140-01-485-1472.). Note: Since an NSN is linked to a qualified product (e.g., 6TAGM battery), it’s possible that multiple manufacturers (or suppliers) are authorized to provide their qualified product under the same NSN.

‣ What is a CAGE Code?

A CAGE code is a Commercial and Government Entity code. It’s assigned by the DoD’s Defense Logistics Agency (DLA) and is used to identify a legal entity (e.g., a business) at a specific location (e.g., Warrensburg, MO). It’s a five-character ID [e.g., the EnerSys® CAGE code for the plant where the Hawker® ARMASAFE™ Plus 6TAGM battery is manufactured is: 0WY95 (note: the first digit is a zero)]. In instances where ordering a specific manufacturer’s (or suppliers) product through the federal supply system by NSN is not feasible, use of the manufacturer’s (or supplier’s) CAGE code in conjunction with that manufacturer’s (or supplier’s) Part Number (or Product number) can be used.

‣ What is a Product Number?

A Product Number is synonymous with a manufacturer’s (or supplier’s) Part Number. For example, the Product Number for the Hawker® ARMASAFE™ Plus 6TAGM battery is: 9750N7025. In instances where ordering a specific manufacturer’s (or supplier’s) product through the federal supply system by NSN is not feasible, use of the manufacturer’s (or supplier’s) Product Number (or Part Number) in conjunction with that manufacturer’s (or supplier’s) CAGE code can be used.

‣ Which Safety Data Sheet (SDS) applies to Hawker® batteries?

Form #: SDS 853027 applies to Hawker® and ODYSSEY® VRLA AGM batteries.